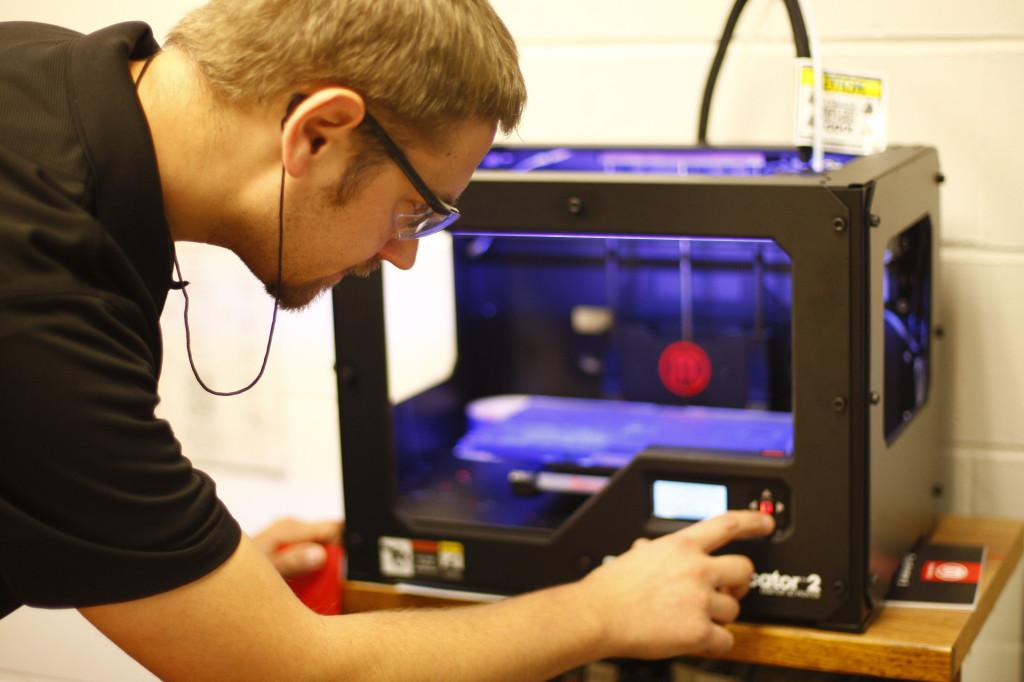

E/T Department 3D Printer

Engineering and technology instructor Paul Cross uses the department’s 3D printer. The department first acquired the printer during the summer of 2013. Photo by Jakob Phillips

This story first appeared in issue two of the Lance.

A layer of plastic in the shape of a Nebraska “N” appears on the LED-lit platform as a small box speeds around, layering a clear, hot glue-like substance. The platform is glass and is in the center of a machine straight out of a sci-fi movie. It is black and the size of a large microwave with the platform in the center, exposed by an opening the size of a microwave door on the front. On the bottom right sits the words “MakerBot Replicator 2.”

The machine works, and engineering and technology instructor Paul Cross takes me to look at plastic objects made with the device. Ten minutes later we return, and on the platform is an eighth-of-an-inch thick Nebraska logo with a hole to attach it to a keychain.

The machine is a 3D printer.

At the end of the summer, the engineering and technology department bought the high-tech apparatus along with a laser engraver.

Cross said the department knew they needed the equipment because students were having to build makeshift parts for robots and other electronic devices out of duct tape, or cardboard or with a hot glue gun.

Now, with the two machines, students are able to build necessary parts.

To make an object with the 3D printer, students draw a design on Google Sketch, then transfer it into an .STL file format. This allows for 3D designs. STL stands for stereolithography, the fancy term for 3D printing. Once it is in the file format, it can be transferred to the printer which does the rest.

For the laser engraver, students must use a computer running Windows XP to access a program that allows them to choose what to engrave or cut. Then, in minutes — six to engrave a Westside logo the size of tennis ball — the laser can put an image on a block of wood, piece of plastic or even metals like aluminum. The engraver can also be used to cut through materials.

For Cross, the two machines have created huge potential.

“I think it really makes it easy for the kids in our class to have an idea and to create something, and I think that is one of the neatest things to do — to have lesson plans for lessons or parts of whatever class you are in, and you have something to take home after that class is done,” Cross said.

Since the mechanisms are so new, students are only allowed to use the mechanisms under close supervision of a engineering teacher.

The teachers want to be sure the printer and engraver are used in a safe manner. As has been mentioned in major news in the past year, especially after the gun control debates that followed the Newtown, CT massacre, 3D printers can be used to make gun parts and could potentially be used to build other dangerous parts.

Cross wants to be sure there is a system in place for teachers to check everything being printed. He hopes to allow his students to use the printer and engraver more freely in the second semester of the school year, if not earlier.

For students who aren’t involved in robotics or other engineering and technology classes or clubs, 3D printing may not be a major part of life today, but the cost of 3D printers is tumbling. They used to be more than $10,000, but the engineering and technology department printer cost around $2,000. With prices in this range, the printers are expected to move into the American home.

“In the future, this could become a household product,” Jenkins said. “It could be like a hand drill, as useful as that. You’d have one out in the garage, and if you broke something you’d just go out to your garage, your 3D printer. You’d find a replacement part and have your 3D printer print it out.”

Senior Caleb Jenkins, a member of the Robotics Club who was able to print a part for a robot, believes the 3D printer will help students learn in a new way.

“It definitely opens up creative thinking a lot because you can think up something, and then make that — absolutely what you needed,” Jenkins said. “You don’t have to cobble anything together. You don’t have to compromise by using inferior parts. You can make something that you need.”

Your donation will support the student journalists of Omaha Westside High School. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.